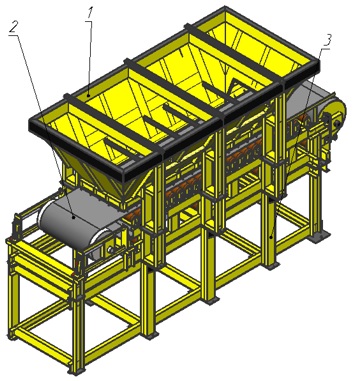

A belt feeder hopper is a stationary or semi-stationary technological installation used for uniform unloading and reloading of grain raw materials to a dump or transport belt conveyor. The belt feeder provides a uniform supply of raw materials of a mixture of quartzite with a size of 0 to 120 mm from the storage hopper to the belt conveyor. The peculiarity of the belt feeder is the ability to unload raw materials up to 120 mm in size from the hopper in a uniform flow. The purpose of the belt feeder is to overload a mixture of quartzite with a particle size of 0 to 120 mm, which is used for the manufacture of electrical products.

Fig. A belt feeder hopper

The equipment shown in the figure consists of a storage hopper 1 equipped with bottom and side openings for unloading raw materials onto the feeder belt 2. This paper considers the process of reloading a mixture of quartzite with a particle size of 0 to 120 mm used for the manufacture of electrical products. The supporting frame of the belt feeder hopper 3 has a complex shape, and is generally designed to safely and reliably support the equipment of the hopper and belt feeder at the required height in order to provide the possibility of reloading raw materials to the main or dump belt conveyor.

The sequence of the technology for loading raw materials into the hopper and further uniform and consistent quartzite feeding is as follows. Raw materials - a mixture of quartzite with a size of 0 to 120 mm using buckets of loading machines are loaded into the hopper. In the hopper, the quartzite mixture moves by gravity to the discharge opening in the lower part of the hopper. The angle of inclination of the hopper walls is not less than 60░. The quartzite mixture is discharged from the hopper onto the rubber belt of the belt feeder. The drive drum drives the belt and transports the raw material to the main or dump conveyors. The raw material flow guides direct the flow of quartzite discharged from the hopper onto the belt feeder, while preventing spillage during overloading onto main or dump conveyors. Adjust the height of the screening layer on the bottom of the tray by varying the belt speed within defined ranges.

In this work, a SolidWorks solid model was developed, technological and design parameters of the belt feeder were calculated, and the parameters of its components were substantiated.

References

1. Bondarenko, A.O., Jamil Haddad, O.O. Tytov, Fadi Alfaqs. 2021. Complex for Processing of Rubble Wastes of Stone Dressing. International Review of Mechanical Engineering (I.RE.M.E.), Vol. 15, N. 1, 44-50. https://doi.org/10.15866/ireme.v15i1.20205.

2. Oleksandr Shustov, Artem Pavlychenko, Andrii Bondarenko, Oleksandr Bielov, Olena Borysovska, Arstanbek Abdiev (2021). Substantiation into Parameters of Carbon Fuel Production Technology from Brown Coal, Actual Challenges in Materials Science and Processing Technologies II, Trans Tech Publications Ltd, Switzerland Vol. 1045, pp 90-101. https://www.scientific.net/book/actual-challenges-in-materials-science-and-processing-technologies-ii/978-3-0357-3883-4.

|