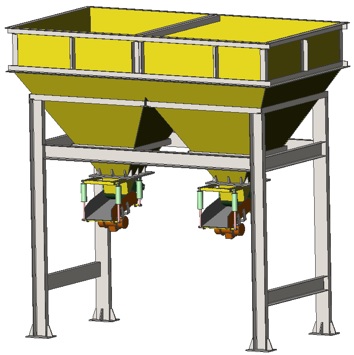

A hopper with vibrating feeders is a stationary installation designed for reloading screenings of labradorite used for the manufacture of building products. The installation shown in the figure consists of two vibrating feeders equipped with a mechanism for adjusting the feeding capacity by a distributed flow of granular raw materials, a hopper equipped with double outlets, which allows unloading raw materials in parallel, a support frame for the hopper with feeders.

Fig. A hopper with vibrating feeders

The principle of operation of the hopper with vibrating feeders: the raw material, namely labradorite screenings, is loaded into the hopper using a front wheel loader. The granular material, under the influence of gravity of its own weight, moves to the outlet and falls on the tray of the vibrating feeder. Under the influence of the vibration caused by the operation of the vibration drive, the grain material moves along the vibrating tray to the discharge area. The angle of inclination of the vibrating feeder tray is selected so that when the vibration drive is turned off, i.e. in the idle state, the granular material lies freely on the tray and is not unloaded. The productivity of the vibrating feeder is changed by adjusting the thickness of the material layer on the surface of the tray.

The advantages of a hopper equipped with double outlets are the ability to distribute the flow of labradorite screenings in two directions, which contributes to the rational further transportation and processing of screenings. The hopper as a whole consists of three parts: the upper parallelogram part of the hopper is designed to increase the volume of raw materials accumulated in it; two pyramidal parts of the same design allow organizing the process of unloading material onto the tray of the vibrating feeder.

The hopper is equipped with vertical and horizontal frames in the upper and lower stiffening belt, which strengthen the parallelogram part of the hopper. The pyramidal parts of the hopper structure are reinforced with horizontal frames installed on the hopper in closed loops. A flange is installed in the lower part of the pyramidal structure of the hoppers to install the structure of the vibrating feeders.

Vibrating feeders are installed using flanges mounted on the outlets of the storage hopper. The design feature of the vibrating feeders is the ability to widely adjust the unloading capacity of raw materials with a size from 0 to 10 mm.

In this work, a SolidWorks solid model was developed, technological and design parameters of the vibrating feeders were calculated, and the parameters of its components were substantiated.

References

1. Bondarenko, A. O., Mal│arenko, P.╬., Zapara, Ievgen, Bliskun, S.P. 2020. Testing of the complex for gravitational washing of sand. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu, (5), 26-32. https://doi.org/10.33271/nvngu/2020-5/026.

2. Bondarenko, A. O., Naumenko R. P. 2019. Comprehensive solution of recycling waste from stone processing industry. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu, 4, pp. 96‒101. DOI: 10.29202/nvngu/2019-4/14.

|