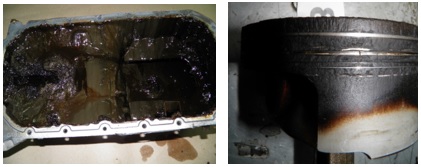

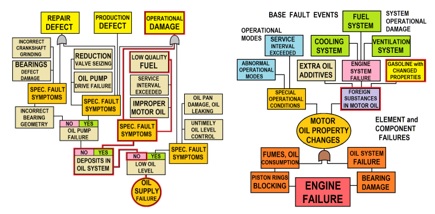

It is known that in the operation of automotive engines, accelerated ageing of oil of normal quality is often observed [1]. In general, engine oil can change its properties as a result of 4 main operational reasons [2], including: faults in engine systems [3]; the use of abnormal modes and conditions in vehicle operation that could affect the properties of the oil [4]; adding various additives to the oil [5]; use the oil does not meet the specifications of automotive manufacturer [6]. Such a change in oil proper-ties often leads to engine failure (Fig. 1).

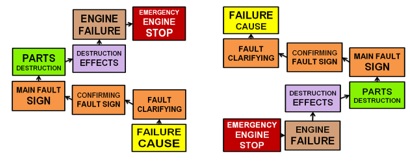

Fig. 2. Forward logic tree (left) for calculating the probability of failure and reverse logic tree (right) proposed to find the cause of failure [7]. The direction of analysis from bottom to top is the same for both schemes.

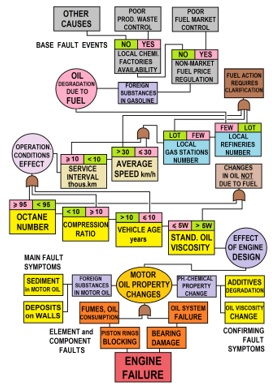

It is clear that for practical use, for example, in tasks of automotive technical exper-tise, it is necessary to expand and detail that part of the general graph of this type of damage that describes the impact of the changed fuel. To this end, it is first advisable to identify all types of effects on engine oil, in order to then identify amongst them those associated with fuel [10]. Then the cause-and-effect relationships of the influ-ence of various factors on engine oil can be represented in the form of the logical graph (Fig. 3).

This graph, as well as the logical chain of clarifying signs (Fig. 3), gives only a gen-eral picture of logical connections, since it takes into account the main events, but does not indicate their signs [11]. In addition, only some of the events shown in Fig. 3 are associated with fuel exposure. Therefore, it is necessary to consider in more detail the causes and symptoms of the logical chain from the changed properties of the fuel through its effect on oil and to engine failure.

Fig. 3. Description of the failure event when abnormal changing the motor oil prop-erties using a logical graph [2]: the symptoms of oiling failure when oil exposure to fuel, when logical analysis is performed in the direction from bottom to top (left), and a simplified logic graph for describing an engine failure event as a result of a general change in motor oil properties in operation (right)

Analysis of the fuel market and known cases of fuel impact on motor oil leads to a number of possible reasons for the appearance of foreign substances in petrol, which can affect the rapid ageing of oil [12]. This could be, amongst other things, non-market regulation of pricing in the fuel market, weak control over participants in the fuel market by the state regulator, the presence of chemical production facili-ties, insufficient control of environmental services over the disposal of industrial waste, etc.

In order for the effect of the fuel on the oil to manifest itself and become noticeable, certain conditions or some secondary accompanying factors are necessary that allow and/or enhance the effect of the fuel to the oil. In particular, these include some de-sign factors, which include the type of fuel, compression ratio, year of vehicle pro-duction, octane number of petrol, initial oil viscosity and some others [9].

In addition to the design ones, it should be noted that there are some associated op-erational factors that enhance the effect of the fuel on oil and the internal combustion engine as a whole. This is an action that depends on the driver of the vehicle, includ-ing the vehicle average speed and the mileage between services.

Fig. 4. An example of a description of the causal relationship between the appear-ance of fuel with altered properties and the engine failure using a logical graph

In addition, there is another group of operational factors that conditionally depend on the driver. This includes, for example, the number of oil refineries, fuel storage bases and gas stations in the operating region. Typically, the more of them, the less likely it is, in general, that modified fuel will enter the fuel tank of a particular vehi-cle when it is refuelled. Then, taking into account the structural composition of the causes, signs and operating factors obtained above, it is possible to obtain a fairly simple logical graph for failure associated with the effect of fuel on oil (Fig. 4).

The algorithm for determining the failure cause means analyzing along the graph in the direction from the engine failure event. In this case, the graph takes into account the entire mechanism of the damage occurrence and development, starting from the base events that initiate the failure and actually determine the failure causes. This makes it possible to use the logical method in expert practice for a preliminary selec-tion the research direction and further clarification the failure causes. At the same time, the graph includes and takes into account practically all known types of motor oil exposure to fuel. With a sufficiently high rate of logical graph details, this helps to avoid gross errors in determining the engine failure cause.

References

1. Johnson D. Turbine Engine Lubricant and Additive Degradation Mechanisms. Aerospace Engineering, 2018. 19 p. DOI: http://dx.doi.org/10.5772/intechopen. 82398.

2. Khrulev A.E., Saraev A.V. Failure mechanisms caused by motor oil degradation and their study as part of expertise of technical condition of gasoline car engines. The National Transport University Bulletin: A Scientific and Technical Journal, 2021, V. 1 (48), pp. 302-314. DOI: https://doi.org/10. 33744/2308-6645-2021-1-48-302-314.

3. Khrulev A. Internal combustion engines: Fault expertise and analysis. Monograph in 2 vol. V.2. Practical determination of fault causes. Chisinau: LAP LAMBERT Academic Publishing, 2023. 562 p. ISBN: 978-620-6-15367-2.

4. Rammohan A. Engineĺs lubrication oil degradation reasons and detection meth-ods: A review. Journal of Chemical and Pharmaceutical Sciences, 2016. Vol. 9. Is-sue 4, pp. 3363-3366.

5. Henning P., Walsh D., Yurko R. et. al. Predictive Equipment Maintenance. Oil Analysis Handbook. Third Edition. Chelmsford, Spectro Scientific, 2017. 120 p.

6. Total. Fuel Dilution of Engine Oil: Causes and Effects. Total Lubricants, 2017. Available at: https://www.lubricants.total.com/news-press-releases/fuel-dilution-engine-oil-causes-and-effects (accessed 20.10.2020).

7. Khrulev A. Principles of development and practical application of logical methods in tasks of searching for the failure causes in internal combustion engines. Proceed-ings of the 9th International scientific and practical conference ôScientists and exist-ing problems of human developmentö (November 14-17, 2023) Zagreb, Croatia, In-ternational Science Group, November 14-17, 2023, pp. 359-363. Available at: https://isg-konf.com/wp-content/uploads/2023/11/SCIENTISTS-AND-EXISTING-PROBLEMS-OF-HUMAN-DEVELOPMENT.pdf.

8. Wakiru, J., Pintelon, L., Chemweno, P., Muchiri, P. Analysis of lubrication oil contamination by fuel dilution with application of cluster analysis. XVII Internation-al Scientific Conference on Industrial Systems (IS'17). Serbia, University of Novi Sad, 2017, pp. 252-257. Available at: https://www.iim.ftn.uns.ac.rs/is17/ pa-pers/45.pdf.

9. Khrulev A.E., Klimenko V.G. Features of composing and application of logical methods for searching of failure causes of internal combustion piston engines in op-eration. Aerospace technic and technology, 2020. No. 7 (167), pp. 146-157. DOI: https://doi.org/10.32620/aktt.2020.7.20.

10. Khrulev A.E. Peculiarities of research the motor oil properties when determining the causes of faults in internal combustion engines. Scientific proceedings of the IX International Scientific and Practical Conference "Technical Regulation, Metrology, Information and Transport Technologies", Odessa State Academy of Technical Regulation and Quality. Odessa, November 14-15, 2019, pp. 157-166.

11. Aircraft Reciprocating-Engine Failure. An Analysis of Failure in a Com-plex Engineered System. ATSB Transport Safety Investigation Report. Aviation Safety Research and Analysis Report. B2007/0191. Canberra City, Australian Transport Safety Bureau, 2008. 255 p.

12. Schwartz S.E. and Mettrick C.J. Mechanisms of Engine Wear and Engine Oil Degradation in Vehicles Using M85 or Gasoline. SAE Transactions. Journal of Fuels & Lubricants, 1994. Vol. 103. Section 4, pp. 1711-1726.

═ÓˇŕţÔŔÚ ŕň│ÔÝŔŕ: ĐÓÓ║Ô ╬Űňŕ˝│Ú ┬│ŕ˛ţţÔŔ¸, ńţŕ˛ţ ˛ň§Ý│¸ÝŔ§ ÝÓˇŕ, ´ţ˘ň˝ţ, ╠│ŠÝÓţńÝň ýţ˛ţÝň ß■ţ