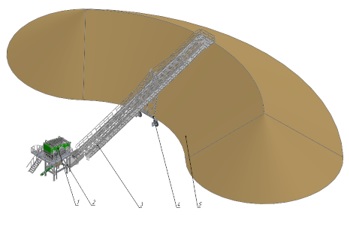

Fig. Crushed stone processing plant

of the complex is shown in the figure. From this rotary stockpile, dewatered crushed stone is loaded onto dump trucks and transported to customers. The complex for crushed stone processing with a capacity of 120 t/h includes a vibrating screen of inertial type 1, supporting structures and service platforms for the screen 2, the screen is equipped with an irrigation system for irrigation of crushed stone particles, a rotary belt conveyor with a capacity of 120 t/h 3, a supporting structure of the conveyor with a rotation system and drive 4, a rotary crushed stone storage facility 5 (Figure).

The rotary belt conveyor of the crushed stone processing complex with a capacity of 120 t/h is designed to transport fine crushed stone cleaned of fine and dusty impurities after its reloading to the stacked warehouse of commercial crushed stone. The rotary belt conveyor of the complex for crushed stone processing with a capacity of 120 t/h consists of a hopper of initial granular raw materials, a tensioning section, an intermediate section, a drive section, a conveyor support frame, a rotary turret, an upper pylon with a rope suspension.

Installation of a rotary belt conveyor should be carried out according to special installation drawings. General attention should be paid to the strict straightness of the conveyor in the plan, compliance with the permissible angle of inclination to the horizon, the required radii of convex and concave sections of the profile, installation of drive and tensioning drums perpendicular to the longitudinal axis of the conveyor, and tensioning drums that deflect, reliable fastening of drive and tensioning stations to the foundations, installation that supports the rollers without distortion, location of the belt joints strictly perpendicular to its longitudinal axis.

In this work, we developed a SolidWorks solid model, calculated the technological and design parameters of a rotary belt conveyor, and substantiated the parameters of its components.

References

Bondarenko, A. O., Naumenko R. P. 2019. Comprehensive solution of recycling waste from stone processing industry. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu, 4, pp. 96‒101. DOI: 10.29202/nvngu/2019-4/14.