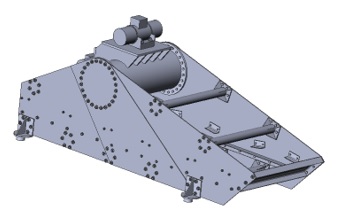

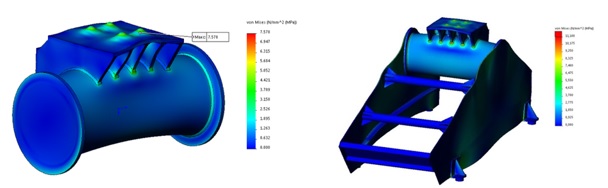

The structure of the vibrating screen needed improvement to increase its efficiency. Two vibration exciters that consist of two parallel shafts with eccentric mass are usually used in the well-known design screen. Shafts are driven by two electric motors. Vibration exciters are fixed on the screen with a flange connection. The solid-state model of the upgraded design has been created using SolidWorks programme (Fig.1).

Fig. 1 ľ Solid-state model of the improved design of the vibrating screen

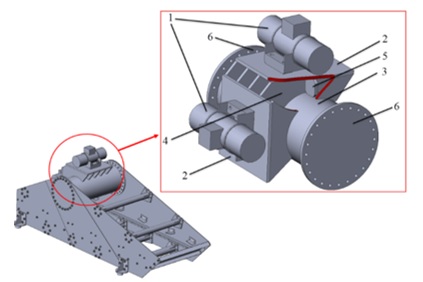

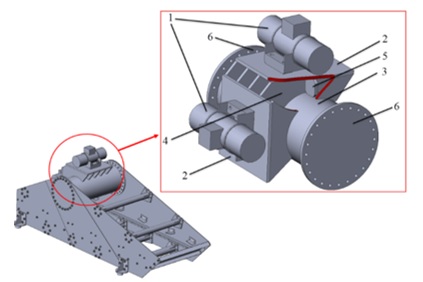

Two vibration exciters are used instead of two unbalance vibration motors (Fig. 2). Installation of vibrators is carried out on a specially designed construction. Vibrator mount consists of horizontal and vertical plates (the vibrators are bolted to the plates), metal tube with longitudinal, and transverse stiffening ribs. Flanges are used to mount the unit to the screen.

1 ľ vibration motors; 2 ľ horizontal and vertical plates; 3 ľ metal tube;

4 ľ longitudinal stiffening ribs; 5 ľ transverse stiffening ribs; 6 ľ flanges.

Fig. 2 ľ Main parts of the vibrator mount

There is a need to determine the durability of the modernized design of the screen for rationale of efficiency. The screen is a complex welded construction. It is not calculated using standard algorithms and requires additional research.

The purpose of the study is to determine the durability of the modernized design of the screen.

The following assumptions are made during the validation of the computational scheme: dynamics task is transformed into static task; crash box is fixed on the base; the interaction of vibrators with the mount is modeled by a force equal to 12.3 kN, which is determined from the technical characteristics of the vibrator.

The solid model screen is simplified for research to determine its durability. Bolted connections and openings for them are excluded. Computer models of vibrators, sieve and metal angles for its support and mounting are not used. An important step in creating a computational model is modeling the welds of the vibrator mount. Welded seams are created as a solid part, taking into account the geometry of the parts being welded.

Angle-free weld seams are used in the manufacture of the screen. This is the reason for the formation of a low penetration zone, which leads to a decrease in the durability of the welded joint. Requirements for modeling welded structures with lack of penetration are: the lack of penetration is modeled as a rectangular slot 1 mm thick between the parts to be welded; the optimal size of the element of the finite element mesh is equal to the width of the gap; reducing the size of the grid element from 10 to 1 leads to an increase in stresses, which indicates the singularity of the problem and the need to apply special calculation methods such as the Hot Spot Stress [1].

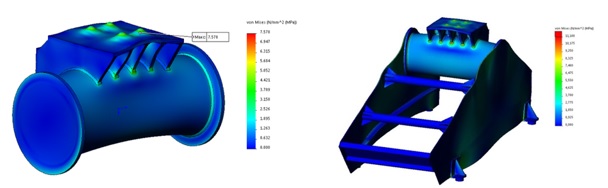

The method of calculating welded structures with incomplete welding is applied to the calculation of the vibrator mount to the screen. The result is shown in Figure 3a. The maximum stresses in the welds occur at the junctions of the middle longitudinal rib with the platform and the pipe. The HSS method should be used to assess the durability of these joints. As a result of using the HSS method, the stresses arising in the welds are 2.5 MPa. The design of the screen is calculated in the same way (Fig. 3b). From the analysis of the results, it follows that the maximum stresses arise in the welds in the node of the vibrator's attachment to the rumble.

Fig. 3 - Equivalent stresses: Ó - in the vibrator mount; ß - in the screen

The allowable stresses are determined:

where ╩ef = 3,5 ľ effective stress concentration ratio;

k - safety factor [3];

σ-1đ = 220 MPa ľ tensile strength limit for steel 45.

If the stresses arising in the construction are lower than [σ], the durability of the welded joints exceeds the cycles, and since the maximum stresses in the welds found by the HSS method are 2.5 MPa, the durability of the welded screen structure is not lower than cycles.

References

1. Recommendations for fatigue design of welded joints and components. ľ [2006]. ľ 147 p. ľ Intern. Inst. of Welding; Doc XIII ľ 1965r14ľ03/XV ľ 1127r14ľ03.

|